Home Page / Products / Seawater Electro-chlorination Hypochlorite

Introduction to seawater electrolysis equipment

JEUDAO seawater electrolysis equipment can use seawater as the water source to continuously produce high-concentration sodium hypochlorite to supply various customers with disinfection needs. The machine can also make low concentration sodium hydroxide solution.

SKU:

Categories:

JEUDAO seawater electrolysis equipment can use seawater as the water source to continuously produce high-concentration sodium hypochlorite to supply various customers with disinfection needs. The machine can also make low concentration sodium hydroxide solution.

Features:

The equipment can continuously prepare high-concentration sodium hypochlorite (NaClO) from seawater species, with a concentration of ≥11%.

The electrolyzer adopts a modular power supply design and n+1 redundancy mode to ensure continuous operation under complex working conditions.

It is controlled by a single-chip microcomputer and runs entirely automatically. After connecting the water source and the output terminal, it automatically runs after power-on.

It supports the automatic switching function of the leading and standby machines and has a self-cleaning system, which requires less maintenance.

JEUDAO independently develops and produces electrolyzers with high pollution resistance and long life.

The capacity expansion is convenient and can be customized according to customer needs.

Name: JEUDAO seawater electrolysis equipment

Machine Model: JD-T100

Equipment power supply: AC 380V 60Hz

Rated power: 5.0-6.0kW

Equipment size: 1050*750*1505mm

Control panel: 10-inch touch LCD

Safety prevention and control: self-contained water level sensor, automatic shutdown when exceeding the standard

Output active chlorine concentration: 10-12% sodium hypochlorite

Water temperature: 5-40℃

Output pressure: 0.2~0.3MPa

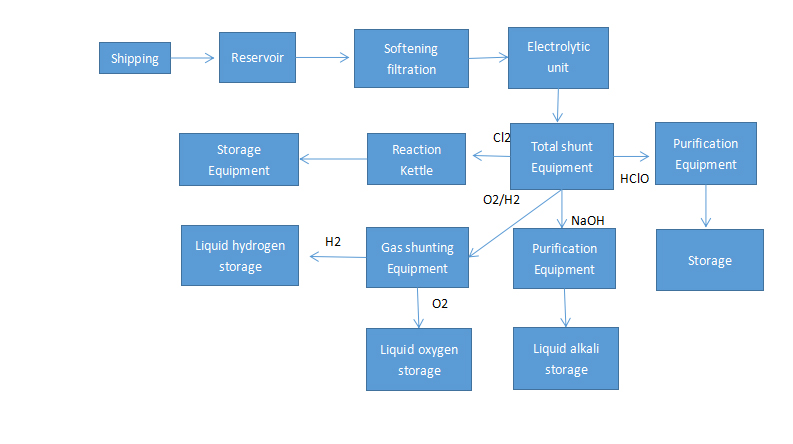

System configuration

①Seawater filter device:

Filter seawater with 1-micron precision to reduce turbidity.

②Seawater electrolysis equipment:

Including the core electrolysis unit, pipes, valves, electrolysis power supply, control system.

③Sodium hypochlorite generation system:

Including sodium hypochlorite reaction tank, pipes, valves, pipe supports, and related accessories.

④Cleaning device:

Including pickling tanks, pickling pumps, pipes, valves, brackets, and accessories.

⑤Hydrogen discharge system

Since a will generate a large amount of hydrogen in the electrolysis process of seawater, the system should control the hydrogen concentration in the workshop to be less than 4% and configure strong exhaust and corresponding alarm concentration sensors to ensure safe operation.

⑥Central control unit:Including:

The control equipment of the whole seawater electrolysis sodium hypochlorite system.

⑦Electrolytic power supply:

According to the voltage standard of the customer's area, filter and rectify the output according to three-phase or two-phase.

⑧Communication module:

The system is equipped with a WIFI module and a 4G Internet of Things module, which is responsible for transmitting the working conditions of the machine to the server and can view the real-time and historical running status of the device at the remote end, as well as fault alarm prompts.

⑨Production capacity:

The adequate chlorine production capacity is 100kg/h (chloride ion in seawater > 15000mg/L), and it can also customize it according to customer requirements.

Working principle

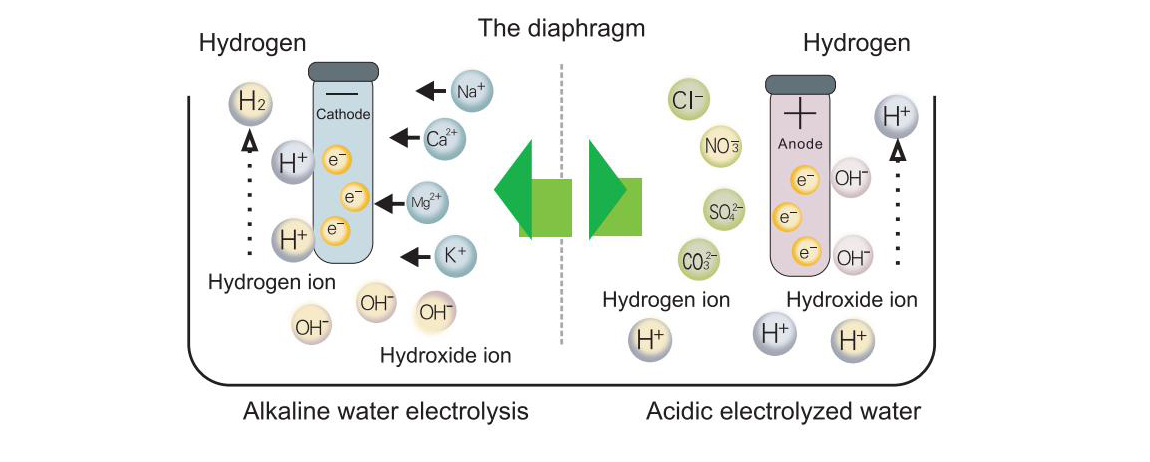

The basic principle of the electrolysis reaction of the membrane electrolyzer is to convert electrical energy into chemical energy, and electrolyze the brine to generate NaOH, Cl2, and H2, as shown in the figure. In the anode compartment of the electrolytic cell (the right side of the figure), the brine is ionized into Na+ and Cl- in the electrolytic cell, where Na+ migrates to the cathode compartment (the left side of the figure) through the selective ionic membrane under the action of the electric charge, leaving behind The Cl- under anodic electrolysis generates chlorine gas. The H2O in the cathode chamber is ionized into H+ and OH-, in which OH- is blocked by a selective cationic membrane in the cathode chamber and combines with Na+ from the anode chamber to form the product NaOH, and H+ generates hydrogen under the action of cathode electrolysis.

Advantages

①JEUDAO's seawater electrolysis system can be flexibly configured according to customers. It can even be made into a miniaturized installation for ships, entering the sea with the ship, and producing high-concentration sodium hypochlorite directly on the ship.If there is a demand for hydrogen collection, It can also produce high-concentration hydrogen at the same time to meet the needs of hydrogen storage.

②The JEUDAO seawater electrolysis unit has high electrolysis efficiency, low energy consumption, small size, and can be deployed mobile. Prepare sanitizer anytime, anywhere.

Production process