Home Page / Applications / How To Use Electrolyzed Water In Cip

In this industry, electrolyzed water technology may open up hundreds of millions of markets in the future...

1.CIP cleaning agent and market expectation

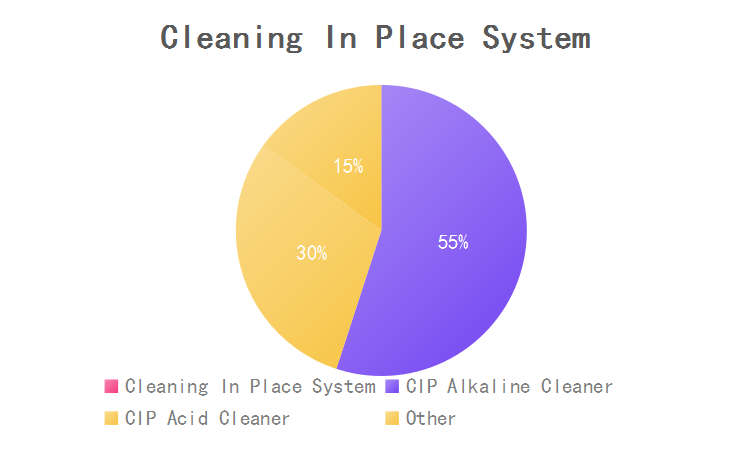

There are three main types of cleaning agents used in CIP cleaning: alkaline cleaning agents, acid cleaning agents and disinfectants.

Alkaline cleaning agents (usually NaOH) are used to remove organic matter; acid cleaning agents (typically nitric acid, phosphoric acid, etc.) are used to dissolve mineral deposits on the surface of equipment, such as calcium and magnesium deposits, complex water lithology, beer lithology, The primary function of the disinfectant is to kill the microorganisms in the pipeline and avoid the influence of microorganisms on the product quality. The commonly used CIP disinfectants are peracetic acid, hydrogen peroxide, chlorine-based disinfectants, etc.

In the CIP cleaning system, the proportion of alkaline cleaning agents is about 55%, the balance of acid cleaning agents is about 30%, and others such as surfactants and disinfectants account for about 15%.

According to data from the National Bureau of Statistics in 2013, the global CIP cleaning agent market has reached 14.52 billion yuan. As a significant market, China occupies nearly 10% of the market share.

2.Ionized water technology

Ionized water, including alkaline ionized water and Acidic Electrolyzed Oxidizing Water (AEOW), has been widely used in food and medical industries as an environmentally friendly cleaning and disinfectant.

Alkaline ionized water that effectively removes dirt such as lipids and proteins.

Acidic electrolyzed water has been proven to have strong bactericidal ability, and its practicability in the field of food processing has also been fully verified.

Acidic electrolyzed water can also be divided into strongly acidic electrolyzed water (also known as acidic oxidation potential water, pH value between 2.0-3.0) and slightly acidic electrolyzed water (pH between 5.5-6.5).

The US FDA has approved the legal use of acidic electrolyzed water in the food and medical industries. The Coca-Cola Company of the United States has specified the use of acidic electrolyzed water as CIP in its bottling plants worldwide.The cleaning and disinfecting liquid of the technology have been installed and used in 3 filling plants in China and have received good results.

The China Beer Association has also included applying acidic ionized water into the "Twelfth Five-Year Plan as a technological innovation project." The Snow Brewery base and several branches of Chinese company use acidic ionized water for disinfection.

3. Research progress on the application of electrolyzed water in beer CIP

In recent years, domestic and foreign scholars and enterprises have done much experimental research on ionized water technology in CIP and proved the application of electrolytic water technology in CIP cleaning.

In 2013, the Food Safety Laboratory of Ocean University of China and the State Key Laboratory of Beer Bio-Fermentation Engineering jointly carried out research on ionized water technology in CIP disinfection of beer production.

The laboratory results show that the acidic ionized water (pH 2.0-3.0, ORP>1100mV) with an effective chlorine concentration of more than 20ppm has an excellent killing effect on Bacillus subtilis, saccharifying yeast, and Lactobacillus Brevis when treated for 5 minutes. 2% peracetic acid can achieve the same level.

In terms of corrosiveness, the corrosiveness of acidic ionized water is slightly higher than that of deionized water, but it is only 20%-30% of the corrosiveness of 2% peracetic acid.

The on-site CIP cleaning experiment results show that using acidic electrolytic water with an effective chlorine concentration of 20ppm for 10-15min cycle cleaning can achieve a good pipeline disinfection effect. There is no need for a clean water wash. Meanwhile, cleaning with acidic electrolytic water will not affect beer's freshness.

In 2013, Beijing Beer Company used neutral ionized water as the bactericide of the brewery. Hydrogen peroxide as the control respectively studied the influence of the residual amount of neutral ionized water on yeast after fermentation tank washing, the effect evaluation of fermentation tank-killing microbial contamination, and the power of residual amount on the activity of anaerobic sludge.

The results showed that the residual amount of 70-80ppm neutral electrolytic water had no adverse effect on fermentation performance after the fermentation tank was rinsed. It can ensure that the sterilization effect of fermenter meets the technological requirements; Neutral electrolytic water with a residual concentration lower than 20ppm does not affect anaerobic sludge activity in the sewage treatment system.

4. Research progress on the application of ionized water in dairy CIP

In recent years, the application of electrolytic water to CIP treatment in the dairy industry has also achieved good results.

In 2005, Walker et al. from Pennsylvania State University studied the cleaning effect of alkaline ionized water with a pH 11.3 and acidic ionized water with a pH 2.6 and ACC of 50-80ppm on milking pipeline model and showed that two ionized water at 60 ℃ was used to clean the milking pipeline for 7.5min. Bacteria and ATP can be removed entirely from the pipe's inner surface, and the cleaning effect is not significantly different from that of the traditional cleaning process.

In 2014, Dev et al., department of Agricultural and Bioengineering, Pennsylvania State University, optimized the application of ionized water in the milking equipment model established and verified the ionized water cleaning model applied to the milking system, again proving the feasibility of using ionized water in CIP process.

In 2017, professors from China Agricultural University used one alkali and one acid (that is, when cleaning the milking system for the first time, except the hot water, only an alkaline cleaning agent was used, and the next time, only an acidic cleaning agent was used; The cleaning method in which the cleaning agent is used alternately in different cleaning processes, but not at the same time).

The actual cleaning effect of 100L vertical milk storage tank was studied by alkaline ionized water (cleaning time: 8 min, temperature: 70.3 ℃, pH value: 12) and slightly acidic electrolytic water (cleaning time: 9.9 min, temperature: 37.8 ℃, effective chlorine concentration: 60mg/L).

The results show that the cleaning mode of electrolytic water - alkali - acid has a good cleaning effect. Compared with the commercial cleaning agent, it can save 74% of production cost and 33% of production water.

In 2018, China Inner Mongolia Dairy Technology Research Institute and others used acidic ionized water and traditional cleaning agents to clean and disinfect the dairy production and ingredient system. After cleaning and disinfection, the microbial residues on the surface of the equipment were collected and analyzed. The two cleaning methods were determined—disinfection effect.

The experimental results show that the cleaning and disinfection of the batching system with Acidic Electrolyzed oxidizing Water can achieve the same effect as the traditional cleaning method; the oxidized potential water can be used as a new cleaning and disinfection technology in the dairy industry CIP.

To sum up, using electrolytic water for treatment in the CIP system has the following advantages:

Ionized water treatment can achieve the same effect as the traditional CIP process.

Ionized water will not produce corrosion on production equipment and pipelines;

The cost of CIP treatment for Ionized water is low.

Ionized water after use without residual, without terminal cleaning;

Ionized water is safer, even if contact with the human body will not cause harm;

Ionized water online generation, more convenient to use.